-40%

Markforged MetalX System

$ 47520

- Description

- Size Guide

Description

The Metal X 3D print system is an end-to-end manufacturing solution — Everything you need to go from design to fully functional metal partsBased on our 4th generation composite 3D printing technology, the Metal X is a brand new kind of 3D printer. By printing metal powder bound in a plastic matrix, we’ve eliminated the safety risks associated with traditional metal 3D printing while enabling new features like closed-cell infill for reduced part weight and cost.

Build Volume:

250

mm

x

220

mm

x

200

mm

Layer Height:

50

μm

Technology:

ADAM

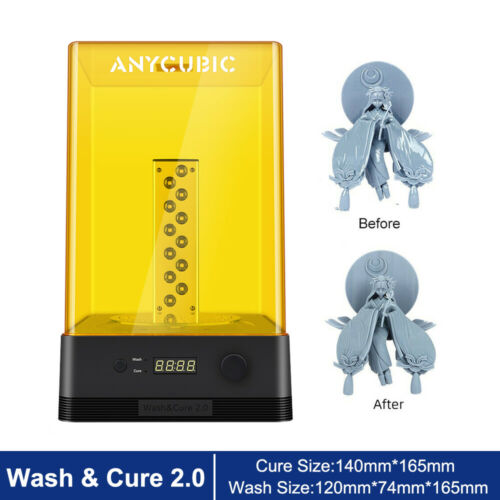

The Wash-1 immerses the green part in a specialized fluid which removes the primary binding material, leaving the part semi-porous so the remaining binder can easily burn off during sintering. This debinding step purifies the final metal part and helps keep your sintering furnace clean.

External Dimensions:

609

mm

x

685

mm

x

1067

mm

Washing Volume:

18,356

cubic cm

The Markforged Sinter-1 is a high performing, high value furnace – it’s affordable, sizable, and reliable. Featuring 4760 cubic cm of working volume, The Sinter-1 effortlessly converts brown (washed) parts into their near fully dense final metallic form. Built on 30 years of Metal Injection Molding (MIM) technology, it is ideal for sintering medium sized parts and small batch production.

Furnace Dimensions:

1067

mm

x

483

mm

x

406

mm

Furnace Volume:

4760

cubic cm

Peak Temperature:

1300° C

This complete set includes aprox.

30gals of the solvent used in the Wash-1 unit.